Shell & Tube Type Heat Exchanger

Shell & Tube heat exchangers are widely used for liquid to liquid and liquid to gas applications such as oil cooling, condensing, jacket water or gas cooling.

MATERIALS

Only quality materials from reputable suppliers are used in the construction of these Heat Exchangers. We carry a large range of stock tubes, and tube plates. Material selection is subject to operating parameters and conditions of use.

Product Description

Condenser | Evaporators | Oil Coolers | Compressor Coolers

Every effort is put in to providing the optimum design of heat exchanger for our client’s conditions taking in to account the performance requirements, environment, safety, material selection and required service life. Our design staff is very experienced and has skill to providing the best & sustainable solution.

Heat exchanger size is calculated to achieve optimum flow regimes in relation to heat transfer, low fouling and scaling. Heat exchanger’s materials are carefully selected so as to minimize erosion and wherever possible we try to use materials that are readily available in standard sizes for short lead times and compatibility with further orders and re-builds.

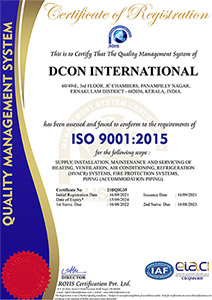

Quality

All units are supplied with full material certification and are pressure tested at our workshop. Heat exchangers are manufactured using proven techniques and inspected regularly throughout manufacturing. We can arrange for third party inspection/witness from most of the internationally recognized independent classification societies.

Whether your need is for a custom designed Shell & Tube Heat Exchanger, de-scale and test, repair or re-tube then just contact us and we’ll be pleased to help.

Product Features

| Model | NA |

| Color | NA |

| Weight | NA |